Hybrid Multi-Agent-System for self-controlling steel production (HyMAS)

In the joint project HyMAS, we are working together with three partners from the Berlin economic area on a future-oriented overall solution for the steel industry. The aim is to develop a Hybrid Multi-Agent System (HyMAS) which should enable self-controlling steel production in the long term. The core component of the desired solution are autonomous software agents that independently, collaboratively and automatically create production plans, monitor their implementation and adjust them dynamically if necessary. This is intended to achieve significant improvements in the dimensions of productivity, energy efficiency and adherence to deadlines

The project brings together the combined expertise of the partners from the fields of information technology (TU Berlin, DAI Labor), production management (TU Berlin, department of industrial production and service management), data analytics (Pumacy) and metal production (PSI Metals). The practical testing takes place in a steelworks in Rhineland-Palatinate.

This project is co-financed by the European Regional Development Fund (EFRE).

Challenges

The manufacture of steel products is not only particularly energy-, investment- and cost-intensive, but also characterized by an extremely high level of complexity in the combination of process and manufacturing processes, complex process conditions, the greatest possible variety and volatile market conditions.

The following challenges in particular are associated with the work in the HyMAS project:

- Complex production environment

- High demands on product quality

- Demanding logistics

- Extreme energy intensity

- High complexity of the calculation of physical product properties

- Analysis of large amounts of data

Implementation

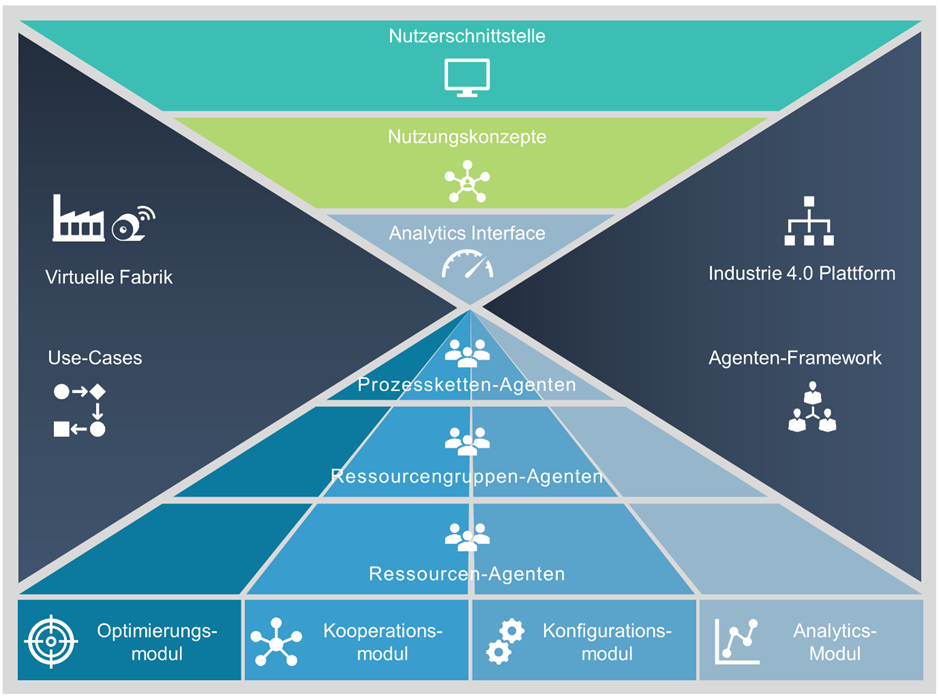

The core components of the HyMAS solution are autonomous software agents that independently, collaboratively and automatically create production plans, monitor their implementation and adjust them dynamically if necessary. Simulation techniques and cognitive algorithms enable predictive and learning behavior. In order to meet the requirements for planning quality, responsiveness and transparency, the agents are embedded in a modular, multi-layer architecture and connected to the rest of the cyber-physical production environment via an existing Industry 4.0 software platform.

For Pumacy, the main focus is on the following topics:

- Analysis and visualization of production and product data

- Monitoring of the calculations and decisions of the HyMAS system

- Support of end users through customized dashboards

- Preparation of predictive models for mechanical product properties

- Early warning of unrealisable product properties

- Support of the automated decisions of the HyMAS system

Objectives

At the end of the project, the implemented SBA (Search-Based Applications) are to be integrated into the user interface of the control center software. This should enable human experts to analyze planning and control decisions of the highly automated Production Management System (PMS) and to influence them in a targeted manner. A special feature here are “hybrid planning modes”. In addition to integrated optimizing planning processes, decentralized, negotiation-based ones are also used. The system should then be able to independently – as required – identify and set the most suitable configuration in each case.

In practice, this is expressed for the user as follows:

- Reduction of the lead or delivery time

- Increase in resource efficiency

- Reduction of the energy requirement

- Lower tolerance in mechanical properties

- Automated optimization of production processes

Technologies used

- Search-Based Applications (SBA)

- Data analytics

- Multi-Agent Systems (MAS)

- Machine learning

- Process mining

Addressed sectors

- Metal processing industry

- Steel mills

- Process industry

Project consortium

Pumacy Technologies AG

PSI Metals GmbH

Technical University of Berlin