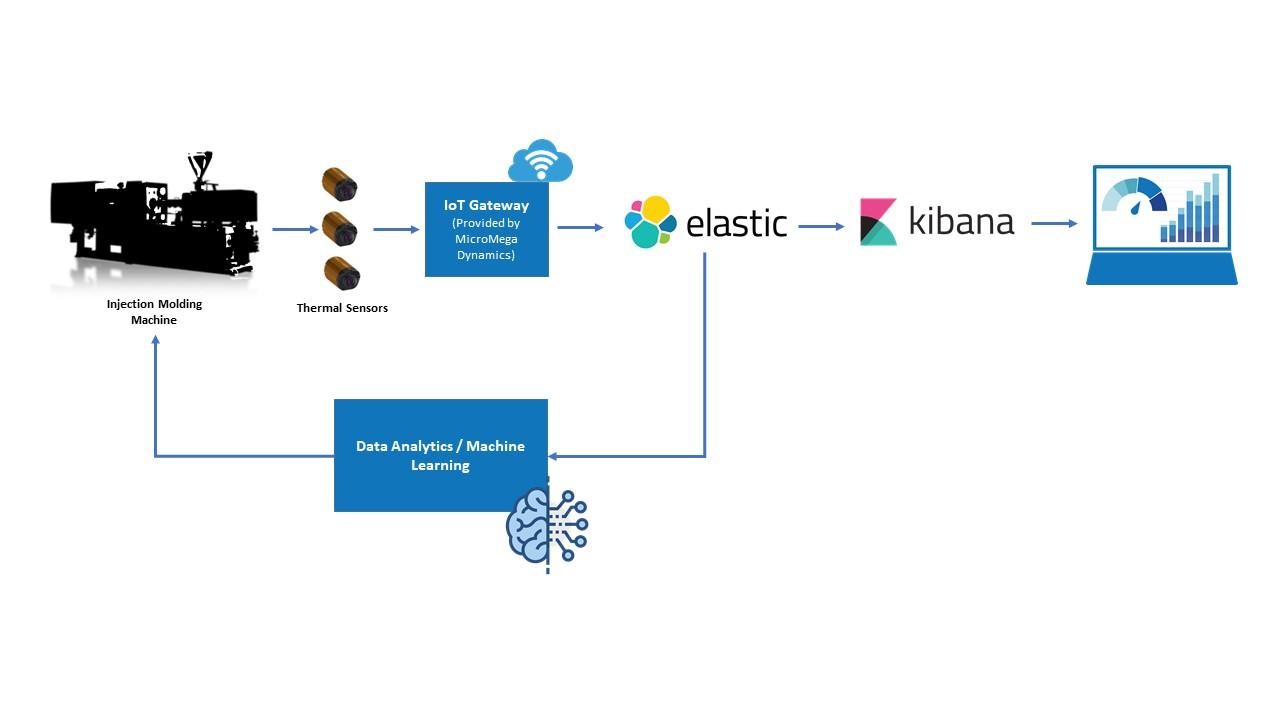

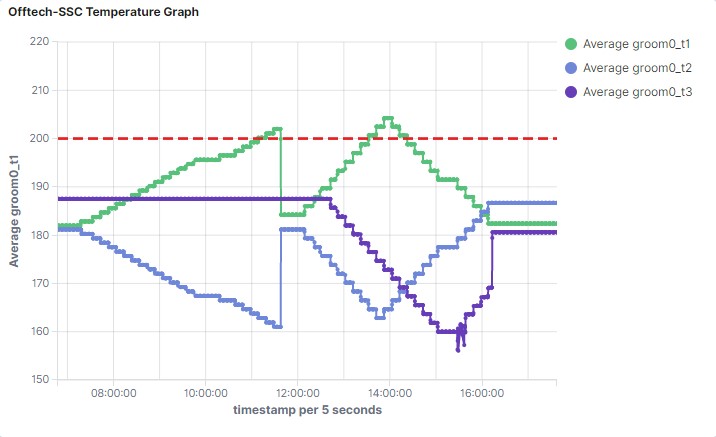

Offtech-SSC focusses small factories with machines older than 12 years. Typically, they do not have any Internet access, WLAN or other connectivity features. Thus, high-end IoT infrastructures nor industry 4.0 solutions of automatization companies won’t make any sense. Consequently, here only works a very practical approach. As practical problem stands the production line of a rubber factory. In this connection, the manufacture of the most products there is subject to a manufacturing process, whereby the final characteristics of the product features are achieved by two precess steps:

(1) Injection moulding with subsequent visual inspection, and

(2) Tempering/annealing with subsequent measurement to ensure compliance with the product specification.